0.00грн.

CheckoutNew models are improvements

Our design and engineering department had time and inspiration. And improved the GFA hydrofilter model.

What changes have been made?

What are the advantages of the new model?

- Full automation of all processes performed by the hydrofilter.

- The hydrofilter can be washed during operation - no need to wait for the facility to close.

- The components of the labyrinth filter that retain the main contaminants are now located in mesh baskets that can be safely and conveniently removed even while the hydrofilter is in operation.

- Maintenance has been made much easier - all the most contaminated parts are removable.

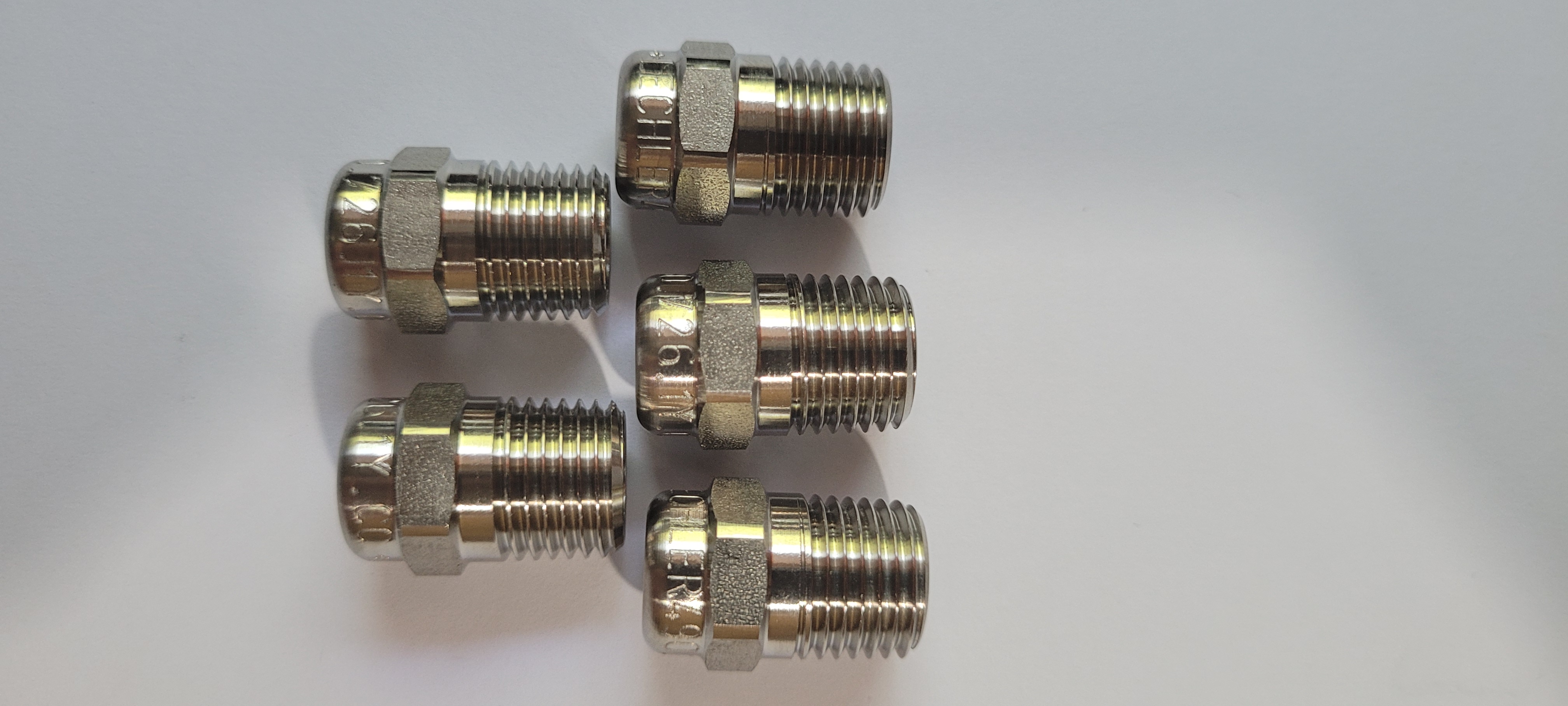

- The location of the nozzles has changed. It has been differentiated to take into account the location of the largest contaminants. The nozzles are now located on the calculated path of the largest contaminants. Water savings and optimal water spray pressure from the nozzles were also present in previous models.

- The range of water filters now consists of either one or two parts - this is decided by the customer based on the layout of the kitchen or other work area.

- The stainless steel canister for detergent, located inside the equipment, has become even more convenient to use.

- If you have purchased a water filter from another manufacturer, you can always upgrade it with our circulation system, which can be purchased separately.

We recommend paying attention to this, because when studying equipment manufactured in other countries, we noticed that there is often insufficient water pressure for 100% spark extinguishing.

Our experience shows that water pressure is important for the hydrofilter to perform its function. Neglecting this is unacceptable.

- The new hydrofilter model also allows you to turn on washing while the hydrofilter is in operation, which is very convenient. This means that you do not need to extinguish the barbecue or stove to perform maintenance. The hydrofilter is washed during the production process.

- We pay close attention to the smallest details to ensure the long-term operation of our equipment. For example, in new models of hydrofilters, we have started to install stainless steel nozzles of improved quality and durability.

We are constantly working to improve our equipment, studying the experience of other manufacturers, making sure that we are the best, but we are not resting on our laurels and continue to improve our products.

We have several more innovations and improvements in the pipeline. More to come.