0.00грн.

Checkout

For years, modern restaurant kitchens have popularly used open flames to prepare food.

The taste of such dishes evokes nostalgia, reminiscent of ancient times, food cooked in an oven or over a fire, outdoor recreation, and holidays at grandma's house.

No electrical equipment can provide such a taste.

By cooking food over a fire, we sell memories and impressions.

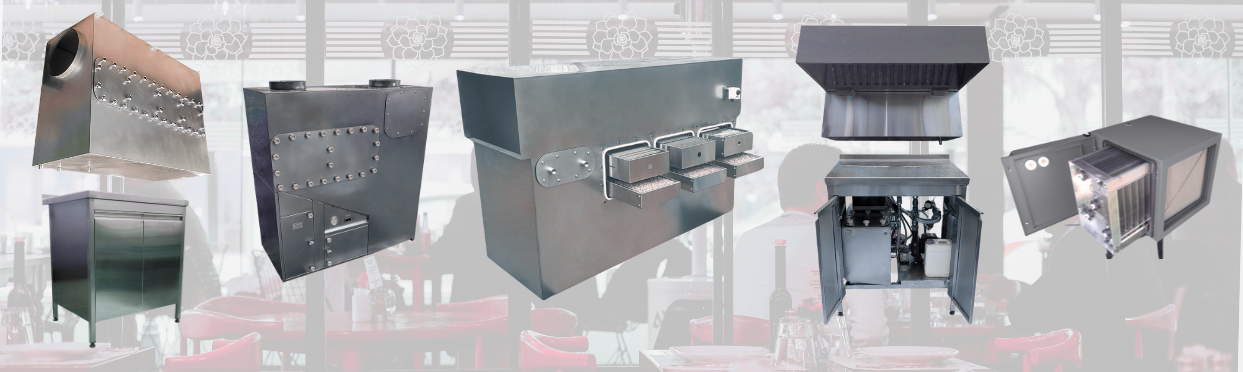

When using coal or wood-fired heating equipment in the kitchen, it is essential to install equipment for extinguishing sparks and purifying the air in the restaurant.

A hydrofilter for a barbecue or oven is both an air purifier and a fire safety device.

Smoke, soot and tar from the barbecue go into the ventilation system. If a hydrofilter is not installed, carbon deposits will build up layer by layer in the air ducts.

This will create a fire hazard due to accidental sparks.

To prevent this, the barbecue is connected to the restaurant's ventilation system via a hydrofilter.

Or the stove is installed.

The hydrofilter completely extinguishes sparks, precipitates soot and smoke, and cools the air and smoke to an acceptable temperature.

Thus, a hydrofilter installed in the restaurant's chimney is mandatory equipment that must be purchased together with a barbecue, hopper or other oven.

Modern restaurant guests will not dine in smoke, fumes and haze, like visitors to a tavern or medieval eatery. Comfort, cosiness and safety should become the motto for restaurateurs.

We can help with this by offering professional equipment for cleaning the air in restaurants.

We offer technological solutions for cleaning the air of soot and smoke, sparks, odours, grease and any impurities in the air. We have equipment for fire safety and odour removal, air purification and smoke removal.

Warranty obligations - one year

Order from manufacturer

Automatic washing during operation

Free delivery throughout the country

A mixture of flame, hot carbon dioxide, smoke, and soot particles bursts out

from the grill or the open doors of the oven - and is immediately drawn into the ventilation system.

To prevent the ventilation system from being

damaged by the hot gases, or from igniting due to soot deposits that should

never accumulate inside, a hydrofilter is installed.

The heated gases containing solid particles

first enter a dense water curtain created by multiple high-pressure nozzles.

This looks like a mist, but with much greater density.

Such a strong and impenetrable water curtain is

unique to our equipment -

because we have conducted extensive testing to determine the optimal pressure

and nozzle configuration. The result is a system that guarantees complete

protection from combustion products.

All unwanted substances are then trapped in

the water, which is drained into the sewage system once a day.

The air continues its journey towards further

filtration.

Removable ceramic cassette filters capture

dispersed hot grease and smaller particles from the gas mixture.

Why removable cassette filters? Because they make maintenance much easier and

keep the hydrofilter convenient to service.

The ceramic filters can be taken out and

washed as needed - typically

once a month, although the frequency depends on your specific kitchen

operations.

Since our systems use a high-pressure water

curtain, droplet separators are installed at the outlet to prevent water

leakage into the air ducts and to provide additional gas filtration.

As a result, the air leaving the unit is dry,

comfortably cool, and contains only a minimal trace of smoke.

If complete smoke elimination is required, we

recommend installing an electrostatic filter, which we also supply.

And for total removal of kitchen odours from the ventilation outlet, we offer a

professional industrial ozone-based air purifier.

Service windows are conveniently located along

the gas path for easy maintenance.

The entire process is controlled electronically, using data from sensors and

measuring devices.

A key feature is the automatic washing system - it can operate even while the

equipment is running.

By the time your restaurant closes for the evening, the hydrofilter is already

clean and ready for the next shift.

Thanks to their powerful air-purification and

spark-suppression systems, our hydrofilter spark arrestors are used not only in

the restaurant industry but also in various industrial facilities.

We also collaborate with ventilation and engineering companies.